Description

Product demonstration of the vegetable dicing machine 3DD cutting vegetables and fruits into cubes/dices, slices and julienne strips:

Vegetable dicing machine 3DD

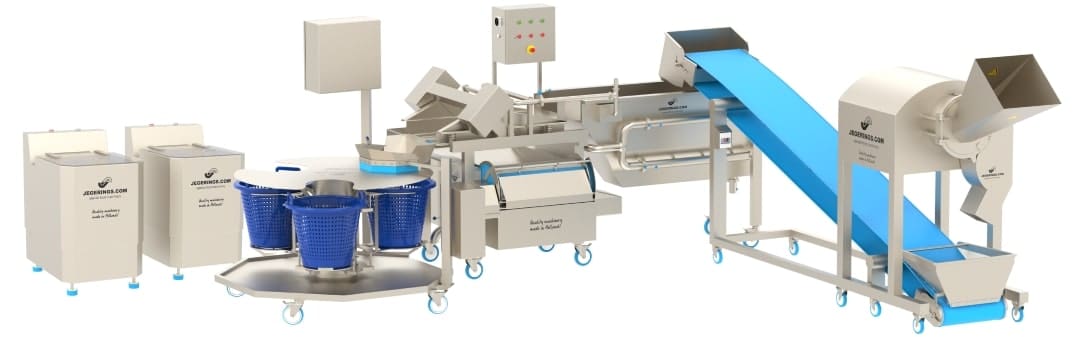

The vegetable dicer machine 3DD is suitable for cutting both vegetables and fruits into cubes, slices and julienne strips. Vegetables will be thrown into the input funnel and are guided to the knives by means of a rotating drum. The three-dimensional cutting system—consisting of a disc knife, a round circle knife and a round chopper—cuts the products while the knives are rotating. Thereby, even the most delicate products are cut perfectly and the loss of product juices is minimal. In short, the 3DD is easy to operate, has an exceptional beautiful and high quality cut, a very solid construction and a perfectly hygienic finish. This dicing machine can also be perfectly integrated into a processing line for cutting, washing and drying vegetables.

Cutting vegetables and fruits

The vegetable dicing machine 3DD is perfectly suited for processing large amounts of vegetables such as potatoes (Belgian fries and French fries), horseradish/daikon radish, beets, turnip, pumpkin, carrots, cucumber, white cabbage, cauliflower rice, celeriac, beetroot, onions, and paprika. This dicer also perfectly cuts fruits such as mango, papaya, avocado, plum, pumpkin, butternut, melon, apple, kiwi etc.

Cutting sizes

- Slices: continuously variable from 1 – 13 mm

- Julienne strips: 2.5 – 5 – 7.5 – 10 – 12.5 – 15 – 20 mm

- Cubes: 3 – 5 – 10 – 12.5 – 15 – 20 mm

Advantages

- Easy to operate: the sets of knives can easily be interchanged. There is only one disc knife and one comb for all cutting sizes

- Exceptionally beautiful and high quality cut

- Minimum cutting waste and no damage to the product

- Excellent safety

- Consists completely of stainless steel

- Completely protected against water

- Easy to clean

- By means of a sustainable construction minimum maintenance and long life span

- Equipped with stainless steel break castors

Technical data

| Capacity | Up to 2000 kg/h |

| Electrical data | 3 Ph / 400 V / 50 Hz / 3 A |

| Power | 1.5 kW |

| Dimensions (LxWxH) | 850 x 1470 x 1690 mm |

| Weight | 261 kg without knives |

FAQ

The 3DD is a three-dimensional cutting machine that processes products in three stages:

- 1st stage: Slicing is accomplished using the slicing knife blade, which comes as standard equipment on the 3DD. You can manually adjust the cutting size of the slicing knife to your desired thickness.

- 2nd stage: In this phase, slices are transformed into strips. To achieve strip cutting, you'll require a circle knife roller with a fixed cutting size, available in cutting sizes ranging from 2.5 mm to 20 mm. Additionally, you'll need a comb that matches the size of the circle knife roller. Even if you're cutting without a circle knife roller, such as French fries, it's essential to equip the machine with a comb.

- 3rd stage: During this stage, strips are further processed into cubes. To accomplish this, you'll need a cross-cut knife roller with a fixed cutting size, available in cutting sizes ranging from 3 mm to 20 mm.

The 3DD dicing machine is known for its very high uniformity and excellent cutting quality. However, it's important to note that the uniformity rate depends on the inherent characteristics of the product and the selected cutting size. The machine excels in achieving uniformity but is subject to the limitations of the product's shape and size. Uniformity levels depend on the following factors:

- Cutting size: Larger cutting sizes may result in variations in the final cuts. For instance, a 10x10x10 mm cut may exhibit more noticeable variations compared to a 5x5x5 mm cut.

- Product size: Generally, larger products tend to maintain higher levels of uniformity.

- Product shape: Products with irregular shapes or hollow interiors may exhibit more pronounced variations compared to uniformly round products.

To further enhance uniformity levels, we provide solutions for handling products with dimensions smaller than the set cutting size. Our washing machines are equipped with a perforated vibrating sieve, designed to filter out products based on the size of the sieve's perforations. Moreover, our optional rotating filter enables you to gather the filtered product, providing versatility for alternative uses.