Description

Product demonstration video of the carborundum potato peeling machine CSM-20:

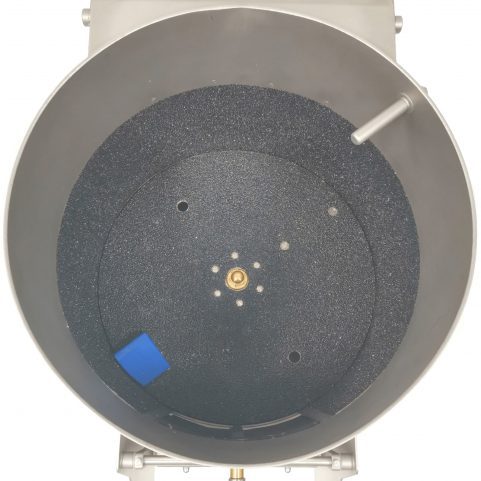

Potato peeling machine CSM-20

- The peeling disc of the potato peeling machine can be taken out of the machine and has curves which makes the products circulate in the machine. Because of this circulation the products are peeled evenly on all sides.

- There is very little space between the disc and the inside skin, which makes it possible that very small products like small potato can be peeled without losses.

- The construction is compact and has a motor which is completely inside the machine. Because of the legs underneath the CSM-20, it is possible to easily clean the floor underneath the machine. The dismountable legs can be sized conform your preferences, before delivery of the machine.

Options of the potato peeling machine CSM-20

- Pneumatic operation of the door, in case of use in a automatic production line.

- A peeling machine with abrasive linen is also available. Because the abrasive linen of the wall is loosely clamped in the inside of the cylinder, it can be replaced quickly and easily. Also the peeling disc can be replaced easily. The peeling machine can be ordered with coarse abrasive linen or with fine polishing abrasive linen.

Technical data

| Electrical data | 3 Ph / 400 V / 50 Hz / 2.7 A |

| Power | 1.1 kW |

| RPM peeling disc | 205 RPM |

| Dimensions (LxWxH) | 530 x 925 x 1042 mm |

| Infeed height | 990 mm |

| Exit height | 525 mm |

| Content per cycle | 15 - 20 kg |

| Cycle time | 1 - 5 min |

| Weight | 125 kg |

FAQ

Using K-16 carborundum effectively removes the product's peel but leaves a textured surface. If you desire a smoother finish, we recommend using a CSM-20 equipped with K-80 polishing carborundum. K-80 is designed to polish the product's surface, resulting in a smoother texture.

The choice between coarse K-16 peeling and K-80 polishing carborundum depends on the intended use of the peeled product. If the product's appearance is crucial, especially when it serves as the final product without further processing, achieving a smooth surface becomes more significant. In such cases, we recommend a two-step approach: begin with K-16 carborundum for effective peeling, followed by K-80 carborundum for polishing. However, if the product will undergo additional processing, where a perfectly smooth finish is less critical, you may not necessarily require the polishing step.

The main distinction is in the peeling process. The CSM-20 uses a carborundum disc and wall, resulting in a smooth, round appearance of the peeled product. In contrast, the MSM-20 employs a knife peeling disc, giving the peeled product flat surfaces, similar to when you peel the product manually with a knife. This hand-peeled appearance is preferred by clients seeking an authentic or artisanal type of peeling.

The CSM-20 is designed to simultaneously peel and spray water on the product. As it peels, any dirt and peel residues are efficiently removed from the product and collected in a basket or drained away through the machine's bottom. There might be some residual starch left on the product that can be rinsed. This integrated process minimizes the need for additional cleaning or washing after peeling, ensuring a convenient and hygienic operation.

The precise cycle time will be dependent on the specific that will be peeled, its ripeness and the quantity per batch. To determine the ideal cycle time, begin by timing the peeling process for a batch until you achieve the desired peeling result. Once you've established the duration, simply input it into the CSM-20's timer. The machine will then operate for the preset time, ensuring consistent and efficient peeling.

In such cases, the CSM-20 offers a pulse button that can be pressed to extend the cycle time for the batch. Simultaneously, the pulse button serves as a means to efficiently discharge the product through the outfeed door of the machine. This ensures that every batch achieves a satisfactory peeling result, providing flexibility to accommodate varying processing needs.